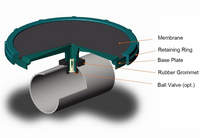

Disc Diffuser

The disc diffuser series combines cost effective design, low installation costs, reliability and performance in intermittent and continuous aeration processes.

- Precision die cut openings for high oxygen tranfer efficiency and performance: The operating pressure can be adjusted to customer or system specification by using different slit patterns varying the number and length of the slits and the spacing between the slits

- Active diameter between 184 mm and 295 mm

- Different standard and special membrane materials specially engineered for a wide spectrum of applications:

- EPDM: municipal wastewater

- Low plasticizer EPDM: animal processing, food processing, beverage production

- Silicone: pulp and paper industry, petrochemical and refining processes

All membrane materials can be equipped with an anti-fouling surface based on nano technology to prevent build up of solids and biological encrustations.

- Glass fiber reinforced polypropylene body plate and ring for maximum chemical, temperature and UV resistance

- Different orifice sizes to adapt various air flows

- Check valve integrated into body plate, optional ball valve available

- Easy mounting on 3-inch and 4-inch IPS pipe as well as 90-mm and 110-mm diameter metric pipe of any thermoplastic material (PVC, CPVC, PP, ABS etc).

- EPDM rubber grommet

- Glue-on PVC saddle (for PVC only)

- Low maintenance requirements

- Standard units in stock for immediate shipment.

Tube diffuser

The Jaeger TD™ tube diffuser series combines cost effective design, low installation costs, reliability and performance in intermittent and continuous aeration processes.

- Precision die cut openings for high oxygen transfer efficiency and performance: The operating pressure (DWP) can be adjusted to the system specification by using different slit patterns varying number and length of slits and the spacing between the slits

- Active length from 200 – 1200 mm with standard length of 500 mm, 750 mm, and 1000 mm

- Mounting onto round and square tube laterals.

- Different membrane materials (can be equipped with an anti-fouling surface based on nano technology):

- EPDM: municipal wastewater

- Low plasticizer EPDM: animal processing, food processing, beverage production

- Silicone: paper and petrochemical industry

- Polyurethane: petrochemical industry