Screws

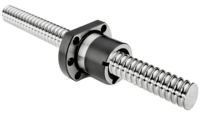

Ball Screws

A ball screw is a mechanical device for translating rotational motion to linear motion with little friction. A threaded shaft provides a spiral raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw.

- D = 12 – 200 mm

- pitch: 4 – 80 mm

- Lmax: 7000 mm

- accuracy class: P1 - T7

Trapezoidal Screws

The trapezoidal thread form is a common leadscrew thread profile that offers high strength with ease of manufacture. It is typically found where large loads or high accuracy are required, as in a vise or the lead screw of a lathe. Standardized variations include multiple-start threads, left-hand threads, and self-centering threads which are less likely to bind under lateral forces. The thread angle is 30°.

- D= 10 – 80 mm

- pitch: 2 – 24 mm

- Lmax: 6000 mm

Miniature TSI & PRM Rolled Ball Screws

Assemblies are an efficient and cost-effective solution in a small envelope, ideal for use in small spaces. Ball screw assemblies range from 4 to 14mm in diameter with leads from 1 to 20mm - all with standard lead accuracies of ±52µm/300mm. Miniature Rolled Ball Screws are ideal for laboratory, semiconductor, and medical applications.

Glide Screws

Part linear bearing, part lead screw, the Glide Screw™ from Thomson combines the best features of these products into an easy to install, one-part solution.

In addition, the Glide Screw eliminates alignment issues and comes standard with Thomson’s patented Lube-for-Life technology for zero maintenance. Additional high heat, vacuum/cleanroom, and food grade configurations are available. If you don’t see a standard model that meets your needs, contact Thomson - we do custom configurations upon request.

Motorised Lead Screws

Motorised Lead Screws from Thomson combine a hybrid stepper motor and a precision lead screw together in one compact envelope. Patent-pending Taper-Lock technology allows quick decoupling and secure, properly aligned connections. Thomson Motorised Lead Screws come in two basic configurations – rotating screw (S) and rotating nut (N). Rotating screw assemblies actuate by having the motor rotate a lead screw and translate a load that is attached to the lead nut. Rotating nut assemblies actuate by rotating a nut within the motor body. Motion is achieved by constraining the motor and translating a load attached to the lead screw or constraining the lead screw and translating a load attached to the motor.

Tech tips

Motorized Lead Screw with Taper-Lock

How to Transfer a Ball Nut to a Ball Screw

Identifying Your Ball Screw Assembly